General Introduction of MicroDelivery Microcapsule

General Introduction of MicroDelivery Microcapsule

update time:2019-04-17

CLICK:

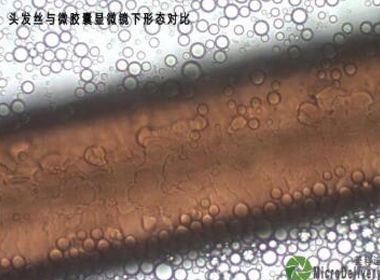

Microcapsule technology is a method in which solid particles, liquid droplets or gases are coated with continuous polymer films thereof to form a small core-shell structure. The diameter of the micro- / nano-scale spherical particles with core materials is only about one tenth or one thousandth of the diameter of hair. (1 micron equivalent to one millionth of a meter, 1 nanometer equivalent to one billionth of a meter) Microcapsules can protect substances from environmental impact, change the shape, density, volume, state and surface properties of core materials, and isolate its active ingredients to reduce volatile and contact toxicity, control its sustainable release and other effects. It can be applied to flavor fragrance, daily washing, food industry, phase change materials (also known as thermoregulation material), pesticide medicine, ink coatings and many other fields.

The main functions of the microcapsules include the following aspects:

-

Change the physical properties of core materials: When liquid or gaseous core material is coated, it can make original form of core material into a solid to get solid oil, solid flavor etc. It is greatly expanding the applications such as fragrance in the food industry. Meanwhile it facilitates the transportation and storage of materials.

-

Improve the stability of core materials: sensitive or active material is coated by the capsule due to the protection of the wall material so that it is no longer in direct contact with the external environment. It can greatly avoid or reduce interference of external environment factors such as temperature, light, acidity, oxygen, effectively prevent or reduce the effective components of the volatile, decomposition, deterioration and other losses. It also prevents the reaction or interaction between materials. Thereby it has greatly improved the chemical and thermal stability of core materials. On the other hand, the encapsulation of core material can improve the compatibility and dispersibility of core material with other blending substances and improve the stability of the product state.

-

Control the release of core materials: polymer wall material coating core material can effectively control the core material (such as fragrance spices) directly release, play a role in slow release. The use of functional response polymer microcapsule wall such as the microcapsules with the pH, light, pressure and other conditions to respond to change, followed by the release of embedded core material.

-

Nanocapsules: as the development of microcapsule technology, microcapsules with 1 to 1000 nanometers diameter are often called nanocapsules. Size to nanometer level can make the performance of the capsule qualitative change. For example, it can pass through the biofilm into cells, tissues and organs. It’s of great prospect that nano-materials with the better transparency do not affect the appearance of the product adding to.

Pain spot of the general microcapsule:

-

Toxic residues. Reaction systems exist harmful monomer residues, such as formaldehyde (carcinogenic and cancer), isocyanate (caused by eczema and bronchial asthma), etc.

-

The capsule shell is fragile. Conventional use of inorganic or natural polymer reaction system for coating, polymerization of silicon dioxide, natural polymers and other wall materials, the strength and stability is not high.

-

Poor controllability of preparation. The shell thickness, microsphere size and other performance control is insufficient.

Technical innovation and product creation of MicroDelivery microcapsule technology:

-

Production system and product is green. Monomer harmless, no reaction of residual formaldehyde and other toxic ingredients, shell material biocompatibility;

-

Coating technology has a wide range of adaptability. General technology platform, oily substances under normal circumstances can be used as general coated materials.

-

High strength of shell material.

-

Good control performance of shell material. Shell thickness and the size of the microspheres can be adjusted according to the practical application.

-

High production efficiency & good product quality. The core embedding rate (that is, the weight percentage of the core material that is successfully covered) is 80% -90%, and the core material loading rate (i.e., the successfully coated core material accounts for the entire microcapsule system by weight) up to 25%-50%;

-

Good product processing performance. The products are microcapsule aqueous emulsion or powdered pure microcapsules, which can be blended with water in proportion, and the oily material is microencapsulated to obtain excellent process ability, compatibility and stability with hydrophilic blends.

MicroDelivery microcapsule green manufacturing technology using harmless monomer and initiator in the water phase polymerization, high degree of reaction, almost no monomer residue, and polymerization of the formation of capsules polymer shell material shows a good quality of biocompatibility. According to product performance requirements to adjust the technical process control capsule size, shell thickness, to make high embedding rate, high containment rate of microcapsules. MicroDelivery green production technology platform has independent intellectual property rights; product performance reached the international leading level.