Microcapsule application technology

VIEWS: 发布时间:2019-04-04

One of the microcapsule application scenarios: isolation reactivity

In production practice, there is a need to integrate reactive, originally incompatible substances into a product system. For example, in the fertilizer industry, silicon is a kind of important crop nutrition, known as the "fourth element", but silicon compounds with plant nutrition are alkaline, and will react with nitrogen fertilizer, so that both silicon and nitrogen fertilizer are lost, and therefore cannot compound with nitrogen fertilizer. Silicon fertilisers have long needed to be applied alone, which adds to Labour costs and discourages their widespread use.

In order to achieve the compound of silicon and nitrogen, phosphorus and potassium nutrients, technicians adopt the microcapsule technology route, encapsulate silicon compounds into microcapsules, and successfully isolate the reactivity of silicon compounds. This technology route can even achieve the production of compound fertilizer containing silicon at high temperature (above 100 degrees), without damaging the microcapsule structure. The cost of the technology is also acceptable to the fertilizer industry.

Most of the coexisting problems with similar active substances can be solved by microencapsulation technology.

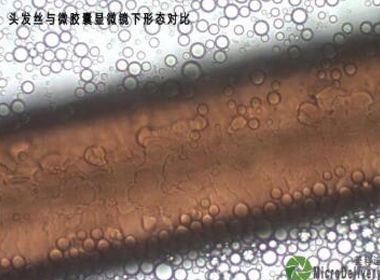

As shown in the schematic diagram of a fertilizer particle, the circle with diagonal lines inside is silicon microencapsulated, and other parts are nutrients of NPK. Since silicon is microencapsulated, it can coexist with NPK without reaction.

Microcapsule application scenario 2: solubilization

In production practice, it is often encountered that some substances have low solubility or poor compatibility in the application system, and it is difficult to achieve the required concentration in the application system without certain technical means.

For example, an oily discoloration dye is only soluble in organic solvents, does not dissolve in water, and can only produce discoloration in the dissolved state. The application environment requires the dye to be dispersed in the aqueous phase and to show the discoloration effect.

Technicians applied the molecular microcapsule technology to encapsulate the dye in the form of a single molecule into the microcapsule, so that it has a good performance of discoloration, and can achieve good dispersion in water.

The structure of the microcapsule is internal oil-wet and external water-wet. The oil dye is sealed inside the microcapsule, and the outside of the microcapsule is hydrophilic, so it can be well dispersed in water, greatly improving the concentration of the oil dye in water.

Microcapsule application scene three: mask taste

In medicine, animal husbandry and other industries, there is often a need to mask the taste, specifically, to cover the taste or smell of some products, so that it is easier to be accepted by users.

For example, there is a drug called andrographolide, which has good anti-inflammatory properties but tastes so bitter that it can make people vomit. By microencapsulation, the drug can be wrapped up so that it will not feel bitter when taken orally, but after entering the gastrointestinal tract, it can be released to play a role in the effect of digestive juices and other liquids.

Feed industry also has similar demand.

Microcapsule application scenario 4: slow release, extended shelf life

By microencapsulating the core substance, the release can be delayed. It is used in pesticide and perfume industry. The outer wall of the microcapsule can also protect the core material, reduce the erosion intensity of ultraviolet light and air, and extend the shelf life.

Microcapsule application scenario 5: liquid powder

Liquid in transport, use is always not convenient, higher requirements for packaging. Technicians used microcapsules to successfully convert a variety of liquids into powder, greatly increasing usability. Now there are powder edible oil, powder wine, powder phosphoric acid, powder glycerin and other products, are achieved through microcapsule technology.

上一个:Application and application of microencapsulated essence

下一个:Ooops!